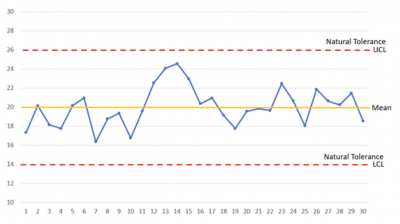

Perform Quality Control Project Quality Management. As demonstrated in the given Graph.

A time-ordered plot of representative sample statistics is called a.

. Is an indication that no cause of variation is present. Your email address will not be published. Use the standard control limit formula and the control chart table to calculate the control limits.

Chart demonstrating basis of control chart Why control charts work The control limits as pictured in the graph might be 0001 probability limits. Tolerances are design specs and are externally imposed by designers. Control chart used to monitor the proportion of defectives in a process.

Ensure you are using the ri ght formula. Set tolerances based on a percentage of the mean 10 or 20. They generally apply to the individual items being measured and appear on histograms box plots or probability plots.

If a point on a control chart falls outside one of the control limits this suggests that the process output is non-random and should be investigated. 1 When Specification Limit Falls between Control Limit. Required fields are marked.

Which is a major advantage of. An X-bar chart and an Individual measurements chart will have different limits. For a stable process the control limits on the chart for individual measurements are _____ the natural tolerance limits.

Process capability compares process variability to the tolerances. Set specification limits based on statistical distributions and analysis. Thus the total room for error is still the same 05 mm but it can go either way from the nominal value by 025 mm.

These lines essentially represent the limit of acceptability. Control charts are data-heavy graphs that illustrate metrics regarding a business or production process based on multiple variables or attributes. An important difference between tolerance limits and control limits is that the former are used to determine whether individual manufactured components are acceptable whereas the latter are used to control the manufacturing process.

An x-bar control chart can only be valid if the underlying population it measures is a normal distribution. These graphs typically display multiple horizontal lines called action or control limits that indicate a serious problem. Control limits should not be confused with tolerance limits or specifications which are completely independent of the distribution of the plotted sample statistic.

Set tolerances based on a worst case margin analysis. An x-bar control chart can only be valid if the underlying population it measures is a normal distribution. Determines if the observations within the limits of a control chart display a nonrandom pattern.

Tolerances are specification limits not control limits. One of the risks of using tolerance limits as a control method during ongoing production is that if you find a part that lies near tolerance limit you. Specification limits are chosen in numerous ways.

Relation between Control Limit and Specification Limit. So we may have to work hard to shiftchange control limit according to specification limit provided to us by our customer. If the natural variability in a process exceeds tolerances.

Pairwise Chart 1 Pareto Charts 1 PDUs 23 Perform Quality Assurance 2 Perform Quality Control 5 Performance Reports 1 PERT 2 Plan Communications 1. The upper and lower control limits are based on the random variation in the process. The tolerance or spec limit is whatever is necessary to produce an acceptable product.

Control limit formula will vary depending on the statistic average range proportion count being plotted. Control limits also known as natural process limits are horizontal lines drawn on a statistical process control chart usually at a distance of 3 standard deviations of the plotted statistic from the statistics mean. Tolerances represent the control limits we use on the charts.

A third way to give a tolerance range is using bilateral deviations. Leave a Reply Cancel reply. Tolerances represent the control limits we use on the charts.

Control limits are the horizontal lines above and below the center line that are used to judge whether a process is out of control. Difference between Tolerances and Control Limits. Tolerances represent the control limits we use on the charts.

Statistical process control focuses on the acceptability of process output. Control limits are one key to process improvement actions. For a stable process the control limits on the chart for individual measurements are _____ the natural tolerance limits.

Limits have a clear link to clinical PK studies or linked from CQAs to unit operations. The control limits of your control chart represent your process variation and help indicate when your process is out of control. Control limits are a statistical measure of the production process.

Guess at tolerances and set arbitrary limits. If you had multiple manufacturing process streams producing the same part it is likely all would have different control limits capability etc but all would have to make products that were within the same set of spec limits and tolerances. False Tolerances are specification limits not control limits.

Control limits are calculated from process data for a particular control chart. Tolerances represent the control limits we use on the charts. What we measure with control charts.

Narrower than wider than cant determine the same as 2. Again shifting or changing control limit is a time taking task. Tolerances represent the control limits we use on the charts.

The drawing states that 9975 as the minimum acceptable dimension and 10025 mm as the maximum. If so and if chance causes alone were present the probability of a point falling above the upper limit would be one out of a thousand and similarly a point falling below the lower limit would be. A point which is outside of the lower control limit on an R-chart.

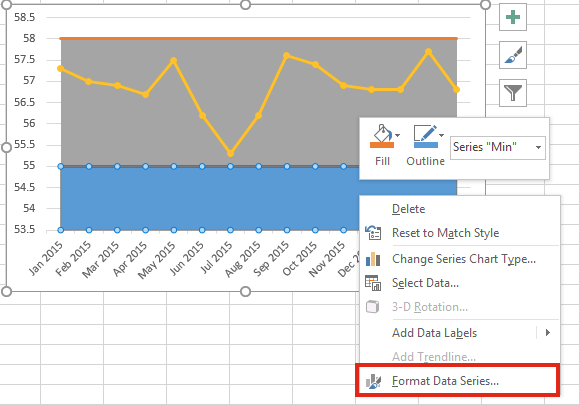

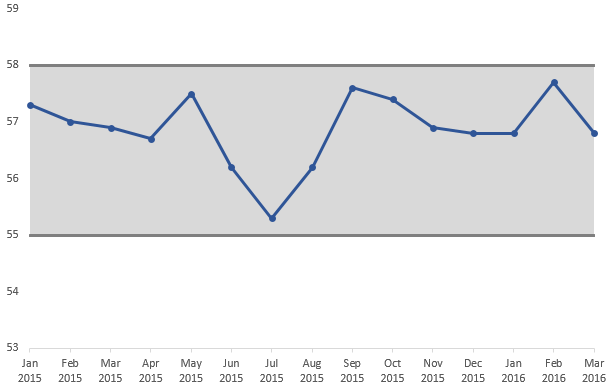

Create A Tolerance Chart In Excel Excel Off The Grid

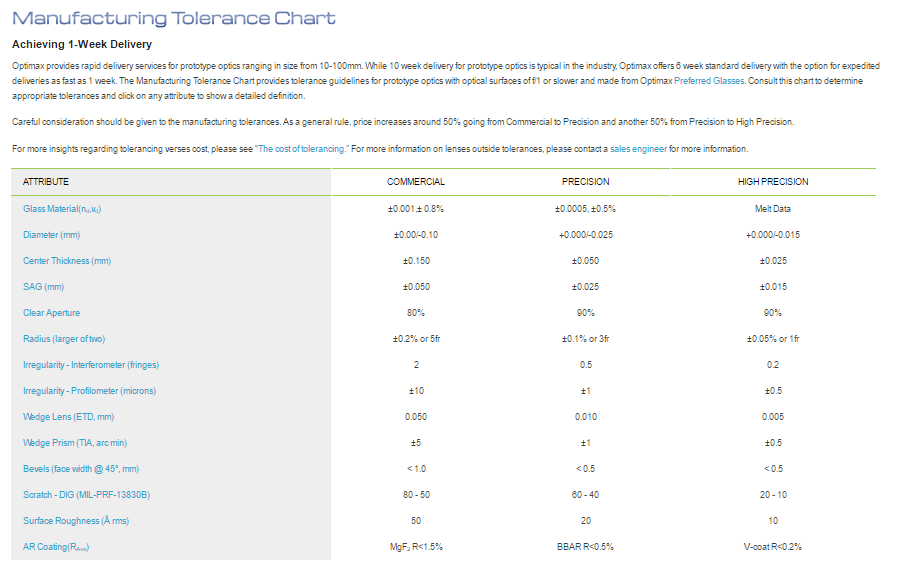

Manufacturing Tolerance Chart Tolerance Guidelines Prototype Optics

0 Comments